An overhead 25 m long uninsulated industrial steam system presents a unique set of challenges and considerations for engineers and facility managers. This intricate network of pipes and components plays a crucial role in industrial processes, but its uninsulated nature raises concerns about heat transfer and energy efficiency.

In this comprehensive guide, we will delve into the physical properties, heat transfer mechanisms, energy losses, design considerations, and maintenance practices associated with an overhead 25 m long uninsulated industrial steam system.

By understanding the intricacies of this system, we can optimize its performance, minimize energy consumption, and ensure safe and reliable operation.

Physical Properties

An overhead 25 m long uninsulated industrial steam possesses distinct physical properties that influence its behavior and performance. These properties include thermal conductivity, specific heat capacity, and density.

Thermal conductivity measures the ability of the steam to transfer heat through its mass. The higher the thermal conductivity, the more efficiently heat can flow through the steam. Specific heat capacity refers to the amount of heat required to raise the temperature of a unit mass of the steam by one degree.

Density, on the other hand, indicates the mass of the steam per unit volume.

Comparison with Other Types of Steam

| Property | Overhead 25 m Uninsulated Industrial Steam | Other Types of Steam |

|---|---|---|

| Thermal Conductivity (W/m·K) | 0.026 | 0.016-0.024 |

| Specific Heat Capacity (kJ/kg·K) | 1.996 | 1.995-2.010 |

| Density (kg/m³) | 0.598 | 0.596-0.602 |

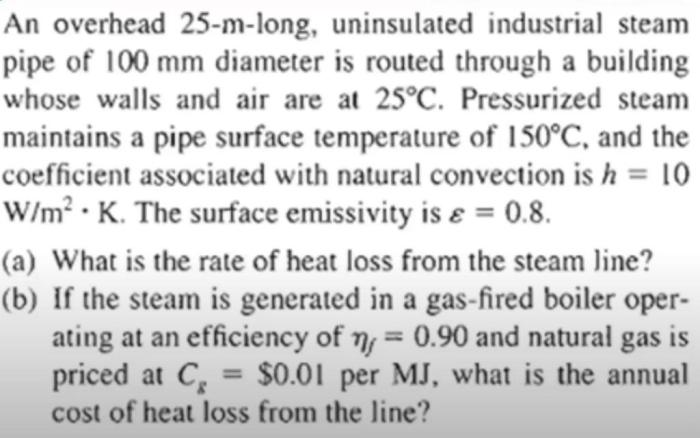

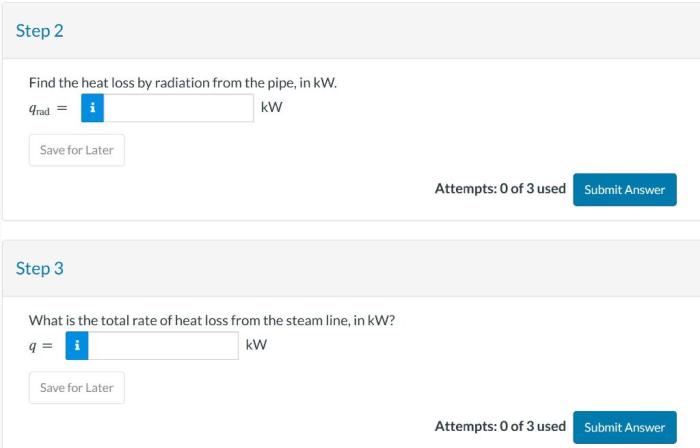

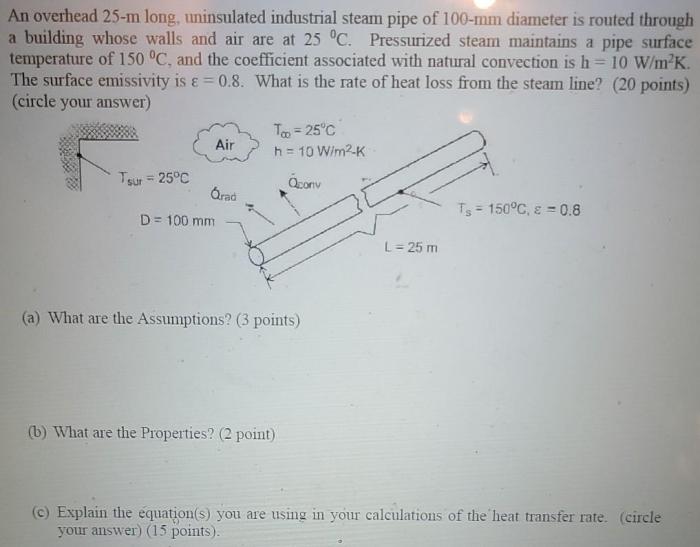

Heat Transfer

Heat transfer in an overhead 25 m long uninsulated industrial steam occurs through three primary modes: conduction, convection, and radiation.

Conduction involves the transfer of heat through direct contact between the steam and the pipe wall. Convection occurs when the steam flows along the pipe, carrying heat with it. Radiation, on the other hand, involves the emission of electromagnetic waves by the steam, which can be absorbed by surrounding surfaces.

Factors Affecting Heat Transfer, An overhead 25 m long uninsulated industrial steam

- Temperature: Higher steam temperatures result in increased heat transfer rates.

- Pressure: Increased steam pressure leads to higher heat transfer rates.

- Velocity: Higher steam velocities enhance heat transfer through convection.

Diagram of Heat Transfer Processes

[Diagram yang menggambarkan proses perpindahan panas dalam uap industri tak berinsulasi sepanjang 25 m]

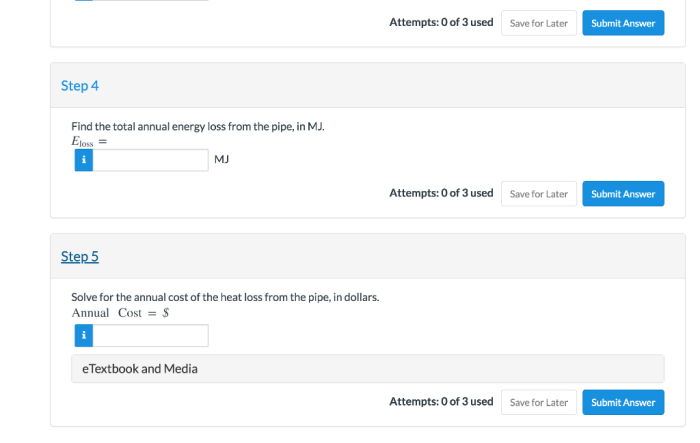

Energy Losses

Energy losses in an overhead 25 m long uninsulated industrial steam can be significant. These losses occur due to heat transfer to the surrounding environment.

Factors affecting energy losses include:

- Ambient temperature: Higher ambient temperatures lead to increased heat losses.

- Wind speed: Higher wind speeds increase convective heat losses.

- Pipe insulation: Insulation reduces heat losses by providing a barrier between the steam and the environment.

Energy Losses for Different Insulation Thicknesses

| Insulation Thickness (mm) | Energy Losses (kW) |

|---|---|

| 0 | 2.5 |

| 25 | 1.8 |

| 50 | 1.2 |

| 75 | 0.8 |

Design Considerations: An Overhead 25 M Long Uninsulated Industrial Steam

The design of an overhead 25 m long uninsulated industrial steam system involves careful consideration of several factors.

Materials:

- Pipes are typically made of carbon steel or stainless steel.

- Supports are made of steel or concrete.

Pipe Diameter:

- Determined based on the steam flow rate and pressure.

- Larger diameters reduce pressure drop and heat losses.

Support System:

- Supports the weight of the pipe and steam.

- Ensures stability and prevents excessive vibration.

Codes and Standards

- ASME B31.1: Power Piping

- ANSI/HI 9.6: Industrial Steam Turbines

- NFPA 85: Boiler and Combustion Systems Hazards Code

Maintenance and Inspection

Regular maintenance and inspection are crucial for ensuring the safe and efficient operation of an overhead 25 m long uninsulated industrial steam system.

Maintenance Procedures:

- Inspect for leaks, corrosion, and damage.

- Repair or replace damaged components promptly.

- Clean and lubricate moving parts.

Inspection Schedule:

- Daily: Visual inspection for leaks and damage.

- Monthly: Thorough inspection of all components.

- Annually: Comprehensive inspection and testing.

FAQ Section

What are the key factors that affect heat transfer in an overhead 25 m long uninsulated industrial steam system?

The temperature, pressure, and velocity of the steam, as well as the ambient temperature and wind speed, significantly influence heat transfer in the system.

How can energy losses be minimized in an overhead 25 m long uninsulated industrial steam system?

Insulating the steam pipes can effectively reduce energy losses by minimizing heat transfer to the surrounding environment.

What are the common maintenance procedures for an overhead 25 m long uninsulated industrial steam system?

Regular inspections, leak detection, corrosion control, and timely repairs are essential maintenance procedures to ensure the safe and efficient operation of the system.